Anatomy of an Ice “Damn”

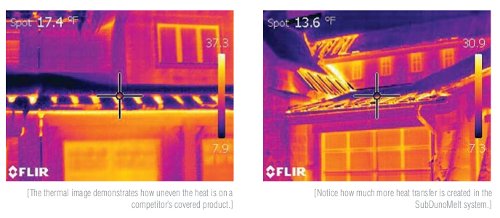

The FixThe key is equalizing the temperature difference on roof in order to stop the buildup of ice. This can be done with a cold roof design or by heating the eaves in some fashion. Let’s take a look at the strengths and weaknesses of each. Cold RoofsA cold roof is one roof built over another with open air space between the two surfaces. The air space above the standard deck is open at the bottom of the eave and runs unobstructed all the way to the top of the ridge. The size of this space is dependent on pitch, eave to ridge length, intake and exhaust length. The more complicated the roof the harder it is for a cold roof to function. If there is not enough intake or exhaust to keep the air flowing through the cavity then a cold roof will not function. heated eaves One important fact to keep in mind with any heat system is if you start to melt the snow and ice you need to keep contact between the heat systems from the top of the heat source all the way to the end of the down spout. Another important rule of heated eaves is that the system must go at least one foot above the warm wall. If a system only goes up onto the roof 6, 12 or even 18 inches but the eaves are 3 feet long you will have freezing between the top edge of the system and the heated area of the roof. This will result in pooled water and the worst of all four letter words, a LEAK! My years of ice dam prevention, repairs and removal helped me develop a completely concealed system that clears the entire eave and follows the rules discussed above. The Sol-Ice SubDynoMelt system clears the eaves completely using heat cable embedded under the roof. This gives the designers, architects and home owners the ability finish the roof as they desire since any roofing product can be installed over the top. The largest SubDynoMelt system we have installed is on the Montage Resort Hotel in Deer Valley Utah. This hotel is at 8,600’ and has over 10 miles of heat cable concealed under the shingles. Chris Piper, Head of Vertical Construction, knew they would have problems if they did not get the right system installed to handle the snow. Talking about his years building in alpine regions Chris said “My experience in the past was that roofers tend to react to the problems of snow country instead of looking at the “Why” and “How”, and providing solutions from the start.” He has also said “Every other snow melt solution has been nothing more than a “Band-Aid” but the SubDynoMelt system has truly fixed the problem.” Never satisfied we sought a better solution than heat cable. We have created a hydronic system called SubHydroMelt. This product has been able to clear snow when heat cable could not, and has produced energy savings to our clients as well. This system is able to operate better than SubDynoMelt or heat cable while costing 90% less to operate. Our clients are extremely pleased with how well our products work for them. If ice dams have been your plague or if you are building a home and want to make sure they don’t damage your investment contact Sol-Ice to design your system or contact our local Authorized Installer Scott Miley Roofing to talk about how our products can be integrated into your next roofing project. For more information contact Dennis N. Duce of Sol-Ice Engineered Systems, Inc. in Park City, Utah at 435.565.1423 or |

[bannergarden id=”1″] |

| [bannergarden id=”2″] | |

| [bannergarden id=”3″] |

Anyone who has dealt with an ice dam knows what a nightmare they can be. The solution is found in understanding how they form. Ice dams buildup as a result of the unequal temperature between the cold eave and the warm roof over the living space. Heat loss from inside causes the snow to melt. Since the eaves are not heated this water freezes causing buildup known as an ice dam. Once the ice grows past the exterior wall it will no longer freeze but the ice dam will hold the water. Since all pitched roofs are designed to shed water this water looks for the path of least resistance. Unfortunately that is straight through all those “covered” but now immersed fasteners holding on the roofing material.

Anyone who has dealt with an ice dam knows what a nightmare they can be. The solution is found in understanding how they form. Ice dams buildup as a result of the unequal temperature between the cold eave and the warm roof over the living space. Heat loss from inside causes the snow to melt. Since the eaves are not heated this water freezes causing buildup known as an ice dam. Once the ice grows past the exterior wall it will no longer freeze but the ice dam will hold the water. Since all pitched roofs are designed to shed water this water looks for the path of least resistance. Unfortunately that is straight through all those “covered” but now immersed fasteners holding on the roofing material.