By Stephanie Dennee

Flooring is the first thing you touch upon rising in the morning and guests’ first impression upon kicking off their shoes at the front door. These surfaces are among the most labored-over decisions in a home, and rightly so. Flooring sets the tone of a home’s visual story while taking the brunt of every coffee spill, every dinner party, and every excited 80-pound dog. The search for the right floor, then, becomes a marriage of lifestyle and aesthetics. Western Home Journal spotlights local professionals dedicated to this happy union.

Montana Timbers

Process Yields Precision

The amount of technology and meticulous work you stand on in your home goes unnoticed. When flooring is made with exceptional attention to detail, the process of creating it fades away, leaving only uniform beauty and comfort to the touch of your bare feet. A deeper understanding of wood flooring fabrication, however, bears a newfound appreciation for what goes into the perennially popular flooring choice. For this, a conversation with Montana Timbers is an advanced placement course in balancing character and precision in the creation of reclaimed wood flooring.

Montana Timbers ships their custom reclaimed flooring, in addition to an extensive inventory of reclaimed timber post and beam, wall material, and exterior products, across North America from their Bozeman-based fabrication facility. While every type of flooring production has technicalities to consider, arguably no flooring fabrication is more complicated than turning the sought-after imprecision of reclaimed wood into precise materials that will stand up to the rigors of flooring applications.

“Before a batch of lumber can even be considered for flooring, we look for characteristics that will produce reliable tongue and groove.”

–Pat Iwanski, Montana Timbers

“Our flooring product uses the highest grade of material we have,” explains Operations Manager Pat Iwanski, as he leads a tour through the Montana Timbers lumberyard. “Before a batch of lumber can even be considered for flooring, we look for characteristics that will produce reliable tongue and groove. Then it goes through an extensive process to further cull out the best product.” The Montana Timbers yard consists of multiple stop-points for each board. Two men diligently pull nails from a load of lumber that was perhaps a worn-down warehouse in Kentucky just a week ago. Then, a series of saws mill that lumber into usable lots. The next stop in the process is two separate types of kilns, each with specific drying capabilities. Along the way are a series of craftsmen shepherding the wood from what it once was to what it will be.

The final stop for wood tagged as flooring grade is the molding facility. There, veteran Montana Timbers employee, Sam Wong, leads a team that transforms reclaimed material into tongue and groove flooring to meet the exact visual specifications of their clients. From the same machinery and wood, they’ll also create trim, stair parts, and other ancillary components. Molding an entire home’s wood order from the same lot of wood ensures a seamless visual transition from flooring to other wood applications. With all these pieces to consider, precision is the principal force in Sam’s work, because millimeters in the molding process can make or break an installation. “Reclaimed material can be all over the place,” Sam says, adding, “Ultimately, you can’t fully control the material, and to some extent, you don’t want to. It’s a balance between keeping the character of the wood while making it piece together just as well as an engineered floor. My job is very much about picking the right lumber to create that balance.”

Pat adds to this notion of threading the needle between character and structural integrity. “Other materials can go on a wall or be used as siding. But the floor you feel every day. It needs to have continued stability over the lifetime of the home,” he explains.

“One of the most important things we do here is to ensure that the moisture level in our wood is adapted to the environment in which it will be installed. Our kilns, designed to dry wood slowly for a desired moisture content, are an essential part of that process.”

–Pat Iwanski, Montana Timbers

Stability is found at the cellular level in wood flooring. Though much of the wood in the Montana Timbers yard was harvested a century ago and naturally aged, the cells within every species of wood still change. Pat explains, “Reclaimed wood, like new wood, can structurally change over time, absorbing or releasing moisture. One of the most important things we do here is to ensure that the moisture level in our wood is adapted to the environment in which it will be installed. Our kilns, designed to dry wood slowly for a desired moisture content, are an essential part of that process. Then, we recommend having the final product sit stacked in the home where it will be installed for a couple of weeks. This time gives the wood a final chance to equalize to its environment before being laid down into place.”

In the cold days of southwest Montana winters, with in-home heat running continually, followed by humid springs and dry summers, the environmental forces that affect any natural wood flooring material are worth special attention. Ultimately, there is no substitute for the combination of original character forged with care that a custom reclaimed floor product can deliver.

Radiant Heat Considerations

The uptick of in-floor radiant heat installation calls for a special approach to both the fabrication and installation of wood flooring. Radiant heat from below can increase the amount of seasonal wood movement. To help soften the appearance and feel of this natural movement, Pat Iwanski of Montana Timbers suggests adding a micro-bevel at the seam between planks. The small edge detail helps visually mask change and keeps the toes and soles of the feet happy all winter long.

Harbour Hardwood Floors

Art You Can Walk On

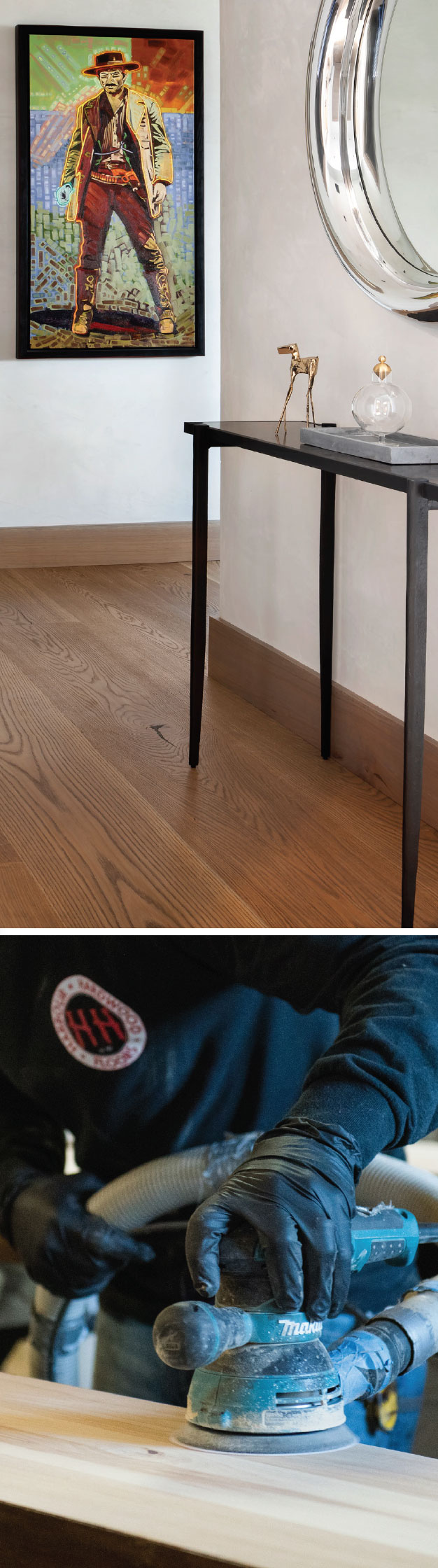

“We all have the same logo on our hat. What that means is a direct line of communication from top to bottom. The design conversations I have with the homeowner or builder are conveyed to the install team. There is no game of telephone in between. That peace of mind goes a long way with builders and homeowners.”

–Andy Gustafson, Harbour Hardwood Floors

When Andy Gustafson walks into a room clad with wood flooring, he does so with his head down. Not because he’s shy. Rather, his downward glance has everything to do with craftsmanship. He is inspecting the grade of the plank and noting the layout of seams and handling of thresholds. This is the trademark tilted gaze of a man who has spent two decades dedicated to the installation and finishing of wood flooring with Bozeman-based Harbour Hardwood Floors. “Everyone on our team stares at floors,” he quips. “Once you enter our field of work, you’ll be that way for the rest of your life. Stuck with that picky eye for detail.” The clients of Harbour Hardwood benefit greatly from that eye for detail, because while selecting a flooring product may seem like the most crucial step of the process, having a talented installation team is equally important. Laying the floor into place with accuracy and finesse means the difference between a so-so surface and an art piece on which you can live.

The position Harbour Hardwood Floors holds in the flooring trade is unique. In most instances, a homeowner purchases flooring from one business and then works with a separate company for installation. In this typical scenario, much can be lost in translation and the proverbial buck can be easily passed. At Harbour Hardwood, their Four Corners-area showroom sells wood flooring products that include both solid and engineered hardwoods, in every imaginable finish aesthetic. Directly below that showroom is the headquarters for the installation and finishing team. The same group manages the process from the initial appointment to a homeowner’s first step onto their new floor. “We all have the same logo on our hat,” says Andy. “What that means is a direct line of communication from top to bottom. The design conversations I have with the homeowner or builder are conveyed to the install team. There is no game of telephone in between. That peace of mind goes a long way with builders and homeowners.”

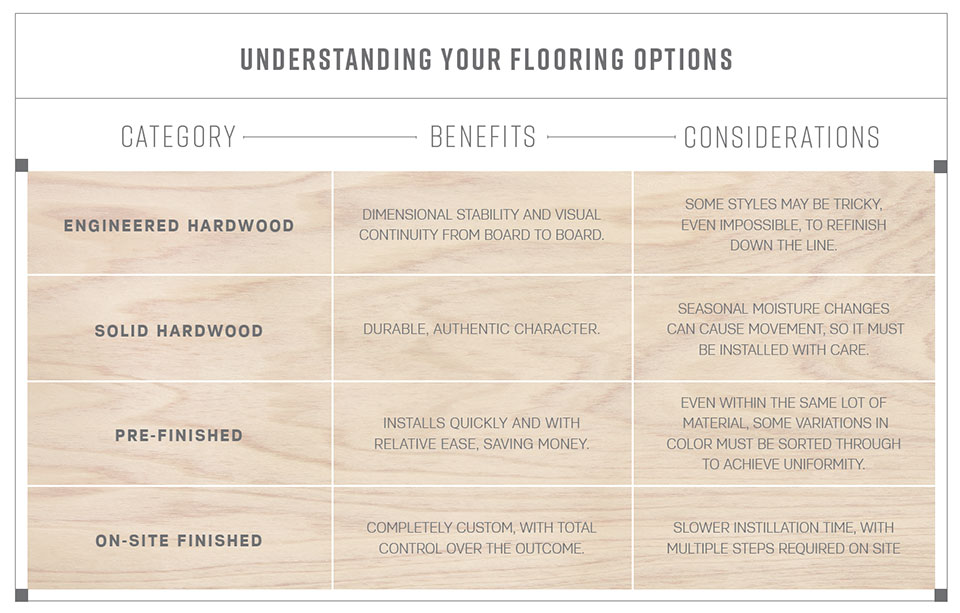

In the showroom, an informational approach on the differences between solid and engineered, site-finished, and pre-finished is where the selection process starts. “There’s a lot of information out there touting one type of product over the other. In reality, they all have their place. It’s important to understand the product choices as they relate to the individual project. Our unique advantage is that we are both the sales and installing team, so we genuinely want to put our clients in the right product for their needs, not just the product that meets a sales objective. Our estimates reflect this, showing how product and installation costs relate to each other. There are no surprises.”

“Our craft is based on a set of foundational principles. So, while styles may change, what we do is rooted in proven procedures…The first and most important rule for our installers is, ‘Listen to the floor’.”

–Andy Gustafson, Harbour Hardwood Floors

Custom, on-site finished hardwoods represent the zenith of craftsmanship in flooring and are the core of Harbour Hardwood Floors’ work. Hundreds of custom finish samples from previous projects line the walls of the shop, each representing a selection chosen by a homeowner. Small mock-ups show a range of finish options, lending sometimes subtle, sometimes dramatic changes across the same piece of maple or oak. “We have decades worth of product experimentation, stain and finish combinations, and technique trials,” Andy says about the toolbox of knowledge they reach into for each project. With that toolbox, they can create virtually any look for their clients, from warm and rustic to a mountain modern polished grey, provincial-feeling wide planks to intricately patterned inlays. When contacted for complex replacements and refinishing of existing floors, Harbour Hardwood has a similarly large toolbox of tricks, and has been part of several notable building restorations, bringing the dilapidated floors of some of Montana’s historical gems back to life.

At the job site, the custom finish decision that started with a sample board in the shop becomes a reality. In talking about this step of the process, Andy’s eye for detail glimmers again. “Our craft is based on a set of foundational principles. So, while styles may change, what we do is rooted in proven procedures,” he says. “The first and most important rule for our installers is, ‘Listen to the floor.’ That holds true through the entire process: sanding, application of stain, and finishing. Our field of work trends toward focusing on small sections at a time, so the importance of reading the floor, stepping back to observe the whole, and adjusting if necessary is the key to our beautiful and lasting final product.”

Gallatin Valley Carpet One

Navigating Design Decisions

“We don’t necessarily like to start on the showroom floor, but rather at a consultation table. Conversation comes first. Questions about desired styling, lifestyle, and goals help the client more than a tour of the showroom.”

–Stuart Beiswanger, Gallatin Valley Carpet One

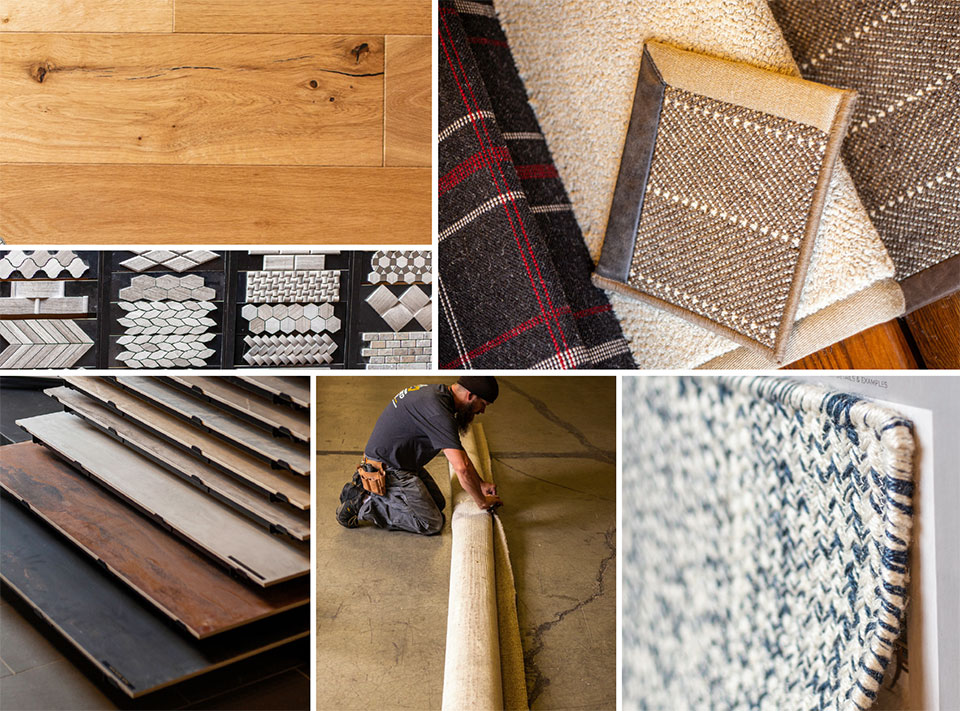

Few categories of home design have as many and as varied options as flooring–from carpet and rugs to every possible variation of wood product, to stone, tile, and concrete. If you can walk on it, it can become a floor. Choosing the right floor can be a complicated process, but much can be done to narrow the scope before even walking through the showroom door. Just as it’s ill-advised to go into a grocery store hungry and without a list, don’t start your flooring search without fielding some basic flooring questions. Define your design style (or styles that appeal to you), define your needs and/or function, and lastly, define your budget.

With so many flooring options to wade through, it’s easy to get distracted by what may lie in the next aisle of the showroom floor. Stuart Beiswanger, owner of Gallatin Valley Carpet One, knows the risk of decision fatigue, so he and his in-house design staff don’t usually start with samples. “We don’t necessarily like to start on the showroom floor, but rather at a consultation table,” he says. “Conversation comes first. Questions about desired styling, lifestyle, and goals help the client more than a tour of the showroom.” He uses a baseball analogy to aptly summarize the process, saying, “We want to establish the outfield foul lines of what is visually appealing to a client. Once those foul lines are defined, the process becomes fun, pulling some options that reach the outer edges of a comfort zone, and some that stay in center field, until we’ve ultimately narrowed it down to home plate.”

The Gallatin Valley Carpet One showroom is a full-service design center, representing hundreds of product lines and one of the few places in the valley that offers a wide range of flooring products under one roof. A staff of trained design professionals—well-versed in each product, their applications, and the latest flooring trends and technologies—are central to the success of the design process. “We often act as a resource for builders and local designers, because we can pull soft surface (carpet) options, next to wood flooring samples, next to bathroom tile, potential countertop, and even cabinetry options. This gives our clients the ability to see the beauty of their design decisions cohesively and understand how the choices in one area interact with materials in adjoining spaces,” says Stuart.

This holistic design and educational approach to flooring includes a look at the budget. “There is opportunity within every flooring budget, places where what is important to our clients can be made paramount,” explains Stuart. “We show our clients ways—whether it be installation savings, product selection, or choosing temporal updates—in which they can save on the overall bottom line without feeling any sense of sacrifice.”

Beyond the budget, durability is a top priority in flooring selection. The Gallatin Valley Carpet One team takes durability one step further, framing it within the context of each individual. Stuart explains: “Durability is not an autonomous attribute. What might be considered durable for one client, in one location, will not hold up at all in another application. We like to think of it in terms of ‘livability’ instead and ask our clients: ‘What will you be doing in this space? Do you have pets? How often do you plan to clean it?’ Knowing the ins and outs of how a person will use their flooring, and how long they want to live with it, is as important as knowing the ins and outs of any specific flooring product.”

Understanding the person who will walk on the floor as well as the flooring product, Stuart says, is what can turn the sometimes-complex task of flooring selection into a rewarding process. “There are many opportunities to purchase flooring in our area. What we provide, what sets us apart, is an experience that can start with a cup of coffee or a beer, and a conversation, and end with a customized, cohesive home flooring plan that can satisfy the homeowner for years to come.”

“There are many opportunities to purchase flooring in our area. What we provide, what sets us apart, is an experience that can start with a cup of coffee or a beer, and a conversation, and end with a customized, cohesive home flooring plan that can satisfy the homeowner for years to come.”

–Stuart Beiswanger, Gallatin Valley Carpet One

Carpet Confidential

Stuart shares some soft surface tricks of the trade.

Buying and storing an extra 8’ x 12’ section of carpeting is your best insurance. In 5 to 8 years, high traffic areas like stairs will start to look worn while the rest of the home’s carpet may last twice as long. Replace that single high-traffic area with your stored carpet, and chances are the whole home’s carpet will feel new.

If you can’t find the right size or style of rug, make it. Purchase carpet (often remnants are available) and have them professionally finished through GVC1. Edging is available in a variety of materials including coordinating fabric or leather expertly matched to your furniture.